Mooney viscosity—PC type fabrication|mooney viscosity rpa : sourcing Mooney Viscosity The Mooney Viscosity test is the most popular test method for characterizing polymers and uncured rubber materials. As defined by international standards, the sample material is preheated for a defined period in a closed die cavity, then 48. sheared by the embedded rotor at a constant rate. The Mooney Viscosity is recorded CADASTRE-SE E FIQUE POR DENTRO. DE TODOS OS EVENTOS! Aceito o envio de dados. Enviar. Rua açaí, n° 111 - Araruama/RJ Bairro: Pontinha.

[email protected]. copyright©2021 Excess Produções. todos .

{plog:ftitle_list}

WEBDownload Telegram About. Blog. Apps. Platform. Join Dani Russo TV - ONLYFANS. 264 subscribers. Dani Russo TV - ONLYFANS. Channel created. 04:31. . Dani Russo TV 🔥 @ .

mooney viscosity test

SKZ132 Mooney viscosity—PC type Used to Raw rubber or rubber compound for the determination of Viscosity, scorch and curing index Feature of host: 1. Computer control, Data display, Automatic calibration 2. Imported intelligent digital temperature controller, easy to .Mooney viscosity measures the stiffness of the uncured compounds, otherwise known as the .Mooney Viscometer controlled by Personal Computer. The mooney viscometer is a shearing .Mooney Viscosity The Mooney Viscosity test is the most popular test method for characterizing polymers and uncured rubber materials. As defined by international standards, the sample material is preheated for a defined period in a closed die cavity, then 48. sheared by the embedded rotor at a constant rate. The Mooney Viscosity is recorded

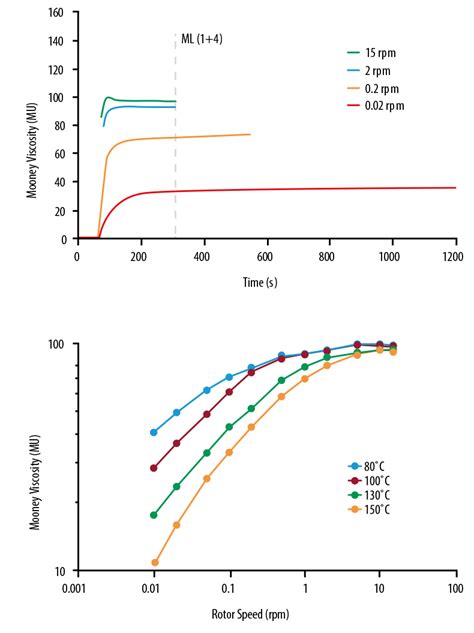

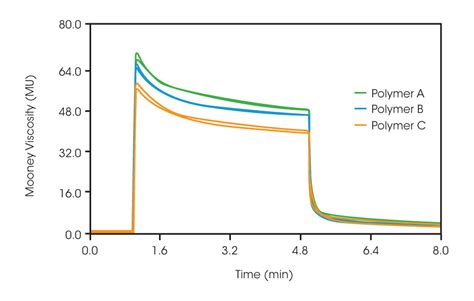

2. Test data: contains the Mooney viscosity, scorch various data; 3. Test curve: Mooney viscosity curve, Mooney scorch curve, temperature curve of the upper and lower mold 4. Modify the time during testing 5. The test data can be saved . It is interesting that the Mooney viscosity for one of the `bad' lots was very close to the Mooney viscosity for the `good' lot (ML1+4 of 93 vs 94). Table 11 gives a description of these three lots. Fig. 31 shows very good separation of the `good' vs the `bad' lots of natural rubber when comparing the uncured tan δ at high strain test conditions. Name: Mooney Viscosity, Stress Relaxation, Scorch Time Instrument/Equipment: Mooney Viscometer Test Type: Cure/Rheological Testing Material: Uncured Rubber Standards: ISO 289, ASTM D1646. For more information on the Mooney Viscometer, such as the Mooneyline Mooney Viscometer model, view the full product specification.

To that end, we investigated Mooney torque relaxation. The Mooney viscometer is an inexpensive instrument (cost and maintenance) that is easy to use and, above all, available in the great majority of factories producing natural rubber. The measurement of NR Mooney viscosity is governed by international standard ISO 289.Overview The MooneyCheck - Drive is a Mooney Viscometer, which permits to measure the Mooney viscosity, Pre-curing (scorch) and Stress Relaxation Characteristics of uncompounded or compounded rubbers In conformity with ISO 289-1, . 아주 대표적인 평가 기기 Mooney Viscometer (무니 점도계)에 대해서 포스트를 해보려고 한다. 대표적인 무니 점도계는 아래와 같이 생겼다. 몇개의 경쟁사가 있겠지만. Alpha Technologies가 개인적으로는 가장 익숙하다. 위의 그림과 같이 .Part 1: Determination of Mooney viscosity. Buy. Follow. Table of contents. Foreword. 1 Scope. 2 Normative references. 3 Principle. 4 Apparatus. 4.1 Typical shearing-disc viscometer. 4.2 Dies. 4.3 Rotor. 4.4 Heating device. 4.5 Temperature-measurement system. 4.6 Die-closure system. 4.7 Torque-measurement device and calibration of the device.

However, if the Mooney viscosity is too low, the physical and mechanical properties of vulcanized products are poor. From the Fig. 4, we can see that with the extension of storage time, the Mooney viscosity of NR shows an increasing trend. The Mooney viscosity of NR goes from 76 to 83 with storage time from 0 to 48 h with a rate increase of 9.21%.5. The maximum test time: Mooney: 10min; Scorch: 120min (modification time during testing) 6. Mooney value of measuring range: 0 to 200 7. Mooney value resolution: 0.1 Mooney value 8. Mooney value measurement accuracy: ± 0.5 Mooney value 9. Calibrate accuracy: 100±0.5 Mooney value 10. Rotor speed: 2 ± 0.02r/min 11. To that end, we investigated Mooney torque relaxation. The Mooney viscometer is an inexpensive instrument (cost and maintenance) that is easy to use and, above all, available in the great majority of factories producing natural rubber. The measurement of NR Mooney viscosity is governed by international standard ISO 289.

literature (Sherman, 1983) is the Mooney's equation (1951). Using functional analysis, Mooney derived the following equation to describe the relative viscosity/concentration behavior of rigid, spherical particles: T/, =exp[2.54>/(I-aM4>)) (1) where T/, is the relative viscosity, 4> is the volume fraction of the solids, and aM isMooney scorch 42, 284 Mooney stress relaxation 46 Mooney tests 37 Mooney viscometer 35, 68, 72 – limitations 51 –For personal use only. variable speed 49 Mooney viscosity 7, 37, 277 Moving Die Rheometer (MDR) 13, 79 Mullins effect 118 – for cured rubber compounds 321 multiple frequency sweeps with increasing

Their Mooney viscosity values were found to be 45.04 and 0.38 MU for samples F3 and F7, respectively. In the case of NR/ENR composites (sample F8), the Mooney viscosity was 13.72 MU, which was lower than that of NR composites. The presence of ENR can reduce the viscosity, indicating good processability and flow properties of rubber composites.

The Mooney viscosity of the sample set was measured by the standard method and the values were in the range 65–95 units. The samples were divided in two subsets, one for calibration, containing 70 samples, and the other for external validation, containing the remaining 30 samples. The Mooney viscosity average values and their standard .

A Mooney viscometer MV 2000 Mooney Viscometer. A Mooney viscometer or rotating disk viscometer is an instrument used for measuring the Mooney viscosity of rubbers. [1] Invented in the 1930s by Melvin Mooney, [2] it contains a rotating spindle and heated dies, the substance encloses and overflows the spindle and the mooney viscosity is calculated from the torque .

Generally speaking, this type of equipment, its operation and the interpretation of the results are too complicated to be used as a standard quality control tool at present. . On Mooney viscosity and Mooney stress relaxation I. J. Appl. Polym. Sci. 1999, 74 pp. 1207–1219 [5]Mooney viscometers are mainly used to test characteristics of raw materials before mixing - to verify that they meet required standards for the formulation in which they are to be used. To perform a Mooney Viscosity Test, the die cavity temperature is set and allowed to stabilize. Then, a specified volume of the sample material is loadedMinimum viscosity (MC) Viscosity value at T5 and T35 ; or T3 and T18 or others; Softening rate and scorching rate curves; Testing temperature curve; Stress Relaxation Test. Relaxation time (Tx) to decay X% of Mooney viscosity % of decay (Xy%) of Mooney viscosity at y sec from rotor stop; Power Law Decay Model Analysis: a-slope ; k-intercept ; A .Certifi cate No. 0395 Certifi cate No. 3088 Technical Specifi cations Design Spec. ISO No. 289/ ASTM D1646 Electrical Single Phase 220/240V 50HZ, 110v 60Hz. Pneumatics Filtered air, 4.2 Kg/cm, (60 Psi) Die Confi guration Standard, large or small rotor Rotor Large or small Rotation Speed 0.21 Radians/sec. (2 rpm.) Calibration Fully automatic Temperature Control 3 .

The Mooney Viscosity of Raw Natural Rubber G.M. BRISTOW* Non-standard Mooney test parameters have been derived for a range of raw natural rubber grades in an attempt to obtain information other than a simple assessment of viscosity. Increasing the pre-heat time to 5 tnin and observing the torque-time relation over 1-4 min

mooney viscosity rpa

Mooney viscometer The sample cavity of the Mooney vis-cometer is shown in Fig. 1. The rotor is embedded in a sample and the torque required to move the rotor at 2 rpm is measured. A typical Mooney viscosity measurement is the ML1+42. This test uses a 1 minute preheat with the motor off and then 4 minutes with the motor on at 2 rpm.of Mooney viscosity with time of oven aging in Fig. (2). As we can see in Fig. (6), the dependence of constant k on Mooney viscosity is in fact linear (r = 0.99916). The constant k therefore cannot provide additional information about oven aging of SMR L rubber to that of Mooney viscosity. Fig. (6). Obtained dependence of constant k on Mooney .

The results have shown that a change of 1 from the test temperature of 100 or 125 results in a 1.5-3% change in Mooney viscosity, depending on the type of rubber tested. 2.2.2. CLOSURE AND HOLDING PRESSURE During the test it is extremely important that the platens and dies be held closed with a force of 11500+500N.3 To obtain the correct .Mooney viscosity ML()1 +4 100°C, but also by Mooney elasticity (a +1). 1. Introduction Natural rubber is a biopolymer originating in trees. Properties of this biopolymer are influenced by genetics of tree as well as by other factors. Characterization of . The SMV-301 / 301RT allows the user to measure the Mooney viscosity, scorch time, minimum Mooney viscosity, and other characteristics of rubber in accordance with JIS, ISO, and ASTM test methods. With outstanding temperature recovery characteristics and easy operability, it can also be used for stress relaxation measurements or for tests that . Multivariable time series forecasting is an important topic of machine learning, and it frequently involves a complex mix of inputs, including static covariates and exogenous time series input. A targeted investigation of this input data is critical for improving prediction performance. In this paper, we propose the fusion transformer (FusFormer), a transformer-based model for .

what does the fda test bottled water for

Closes #9053 and #8949 - 47.1.35 Replace string with forge tag in vanilla recipes. Closes #9062 - 47.1.34 Fix new brain hooks not persisting active activities. - 47.1.33 Fix breaking overlay flickering on campfires by using vanilla method to calculate block normals. (#9664) - 47.1.32 Cleanup usages of static imports and build script so that our .

Mooney viscosity—PC type fabrication|mooney viscosity rpa